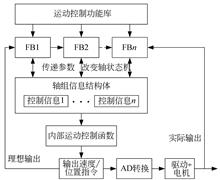

A motion control function library comprises a set of standard functional blocks integrated in a programmable integrated environment, which is vital to the rapid development of reconfigurable PAC systems. To solve the problems associated with the rapid development of functional blocks and the standardized development of control systems, the development methods and key technologies of functional blocks are investigated in this study; In addition, a motion control function library architecture based on the PLC open specification and its rapid development method are proposed. First, the servo control principle of classical electromechanical equipment is investigated and analyzed, and a series of motion control function libraries are developed via domestic programming and development tools. Subsequently, based on the idea of software-defined machines, a motion control system of mechanical and electrical equipment is constructed via graphical programming and then verified on a high-precision rotating double prism. Experimental results show that the developed functional block can complete the target motion and that the highest interpolation accuracy achievable by the autonomous controllable system is 0.3 mm. Therefore, the proposed development method for functional blocks and function library architectures can satisfy the control requirements of most electromechanical devices.

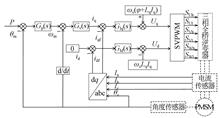

To avoid safety accidents caused by the unexpected movement of mechanical parts during equipment manufacturing, this paper investigates the safety integrated design method of the servo drive module according to the IEC61800-5-2 standard. First, the principle of servo drive module is clarified by analyzing the mathematical model, hardware structure, and functional architecture of the servo drive. According to the principle, the failure mechanism, failure mode, and effect of failure on the system are discussed. The safe operation interval based on parameter constraint is established, which can actively monitor the dangerous failure of the servo drive module. Then, by analyzing the characteristics of 17 safety functions suggested by IEC61800-5-2, the architecture of safety related system is designed, and a method for safety function integration based on object dictionary is proposed, which can realize the configuration of safety functions according to the specific security requirements. Finally, the experimental platform is built, and the typical safe logic is designed to verify the safety integration method. The experimental results show that the proposed functional safety integration method can effectively implement the IEC61800-5-2 recommended safety functions through configuration, and it meets the requirements of the servo drive module to generalize the safety functions.

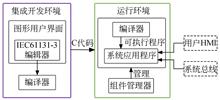

The master station programming tool is an important component of the visual design, download, and operation of the whole logic function and motion control function programs of a programmable control system. To break the foreign monopoly on industrial control software platforms, the development of a safe and reliable master station programming tool serving an autonomously controllable, programmable, control system, is paramount. This paper investigates the design method for each component of the master station programming tool chain. First, according to the working principle of an open-source integrated development environment (IDE), a software architecture for the master station programming tool based on IEC61131-3 is proposed. Then, the plug-ins for bus configuration and data access in the IDE are designed from the perspective of generating code integrity, and the architecture and components of Runtime executed by the master code are also designed, forming a fully functional programming tool chain. Finally, taking two basic safety functions as examples, the integrated development method of the IEC61800-5-2 functional safety basic library is analyzed. The experimental results show that the master station programming tool designed in this paper has functions such as visual programming, downloading, and running, and it meets the basic program development requirements for autonomously controllable, programmable, control systems.

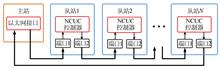

In a bus-based control system, the transmission rate and synchronization accuracy of the fieldbus are key factors affecting the speed and accuracy of multi-axis collaborative machining tasks. To satisfy the performance requirements of high-speed and high-precision manufacturing equipment, the transmission rate and synchronization accuracy of the control system must be optimized and the information security of industrial communication must be ensured. Based on domestic FPGA chip, a general Ethernet interface circuit that conforms to the IEEE802.3 specification is designed and a linear cascaded network topology is constructed in this study. Considering the channel transmission principle of industrial control process and service data, a data transmission method for channel mapping is proposed, improving the bus efficiency. A distributed clock synchronization mechanism is used to calculate the network transmission delay and time offset using timestamps, and synchronization control is achieved by compensating for the bus controller. Experimental results show that the designed high-precision synchronous real-time Ethernet bus controller can achieve a minimum communication period of 250 μs in a 100 Mb/s Ethernet link, and that the synchronization accuracy of each node in the network is less than 50 ns, which corresponds to the international advanced level.

This study aims to address the technical blockade of programmable control systems, which are the core control component of manufacturing equipment, and to break through complex technical systems for the integration of mechanics, electronics, computer science, bus communications, and other disciplines. In addition, it responds to the "Made in China 2025" and "Industrial Strong Foundation Project" independent and controllable development goals. This study analyzes the development process and technical system of a programmable control system and proposes a composition scheme based on a real-time Ethernet field bus. The working principle and key technologies of the field bus, master-slave hardware, software integrated development environment, man-machine configuration software, and other components in the composition scheme are explained. Furthermore, various research methods and the development of a technology ecology are proposed to achieve independent controllability. The solutions for key technologies provide a reference for the safe and stable development of the Chinese equipment manufacturing industry.